If you’ve been to a pro lighting tradeshow in the last few years, you will have seen the brutal punishment that SGM dish out to their IP65 rated fixtures to prove how serious they are about weather proofing – sitting in ponds with jets of water trained on them, sitting under waterfalls, and copping immersions in any other way SGM can dream up. While protecting a fixture from water ingress is one thing, deciding what to do if water DOES get in is another.

An IP65-rated lighting fixture normally utilises a polytetrafluoroethylene membrane (commonly marketed as GORE-TEX) to equalise the air pressure between the interior of the fixture and the exterior environment. The equalisation of the air pressure is an essential part to protecting the seals in the fixture from breaking.

When power is connected to a LED light it generates heat within the light source, which causes the air pressure inside the fixture to increase and the contained air to expand. The expanded air will pass through the polytetrafluoroethylene membrane, equalising the air pressure both inside and outside the fixture. When the temperature inside the fixture is cooler than the surroundings, the air pressure inside the fixture will be lower than the outside air pressure, causing air to be sucked in via the polytetrafluoroethylene membrane until pressure is equalised.

However, if the surrounding air contains humidity, this will be sucked into the fixture along with the air, since the polytetrafluoroethylene membrane cannot prevent humid air and other gasses from entering the fixture. Ultimately, this process increases humidity level inside the fixture.

SGM’s patented Dehumidifier, incorporated in the SGM product range, constantly (when connected to mains power) removes trapped hydrogen from inside of the

lighting fixture in a solid state electrolytic process with no moving parts.

When the humidity concentration reaches a certain level inside the fixture, it will eventually condensate and lead to corrosion. This process, then, leads to a degeneration of the lighting fixture as well as a reduction in the product’s lifetime. Along with humidity, air pollution that contains H2SO4 (sulfuric acid) will enter unhindered through the polytetrafluoroethylene membrane and into the lighting fixture, further causing destructive corrosion.

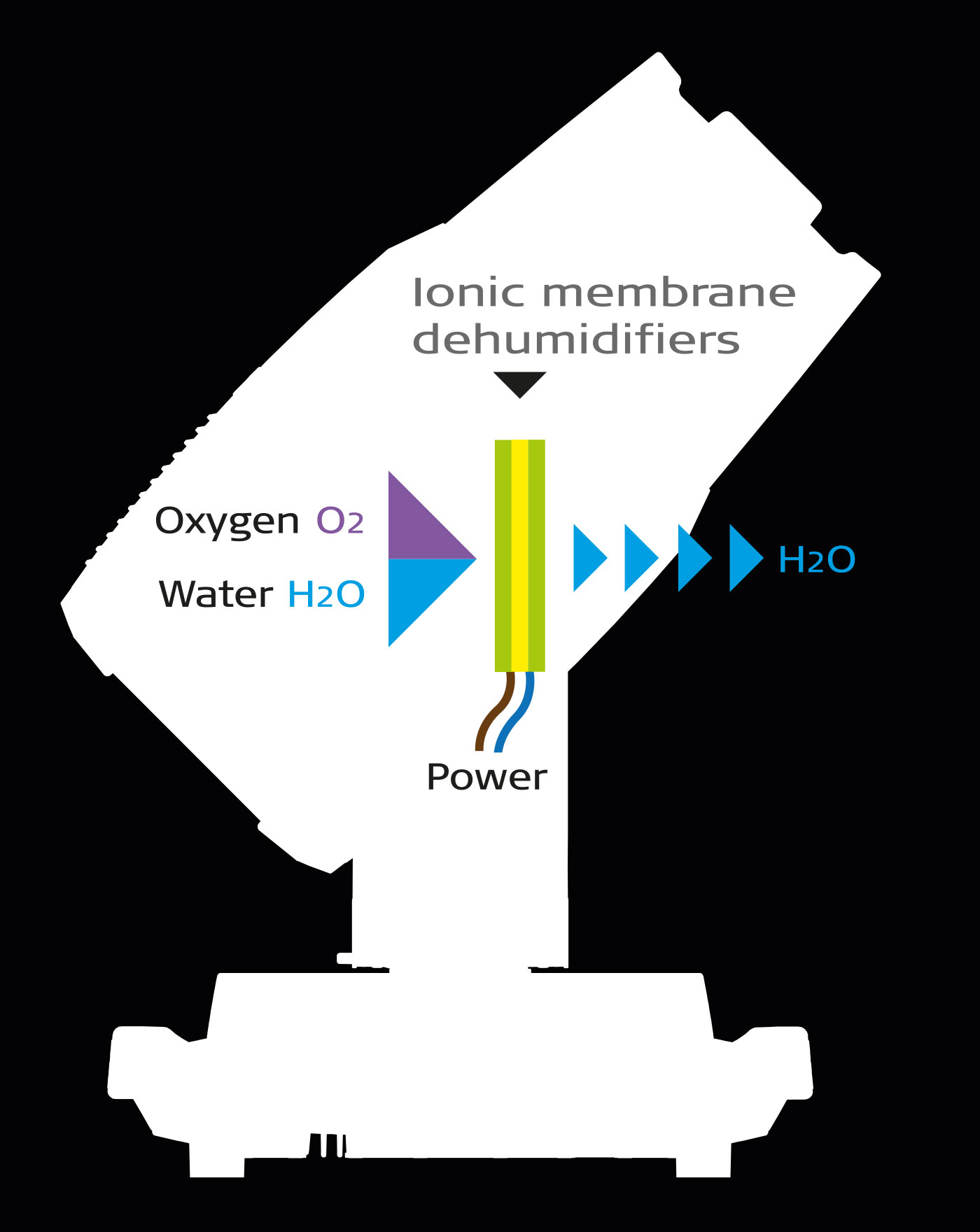

SGM’s patented Dehumidifier, incorporated in the SGM product range, constantly (when connected to mains power) removes trapped hydrogen from inside of the lighting fixture in a solid state electrolytic process with no moving parts. SGM’s Dehumidifier breaks down corrosive H2SO4 molecules, derived from polluted air, and eliminates the effects thereof. This unique process eliminates any risk of humidity, which would otherwise lead to condensation and corrosion.